Many think an oil filter is fine as long as it “doesn’t leak.” But in the eyes of automotive engineers, it’s the engine’s “blood purifier.” The entire core of its cleansing power lies hidden within a single, small piece of filter media. Overlooking the performance of this media means even the cheapest filter is just an empty shell.

The Core Mission: Filtration, Pure and Simple

The fundamental job of an oil filter is to remove contaminants from the oil, maintaining its cleanliness to extend the life of both the oil and the engine itself. Without effective filtration, it holds zero value. And almost all filtration performance is determined by one thing: the quality of the filter media.

The Filter Media: The Decisive Element

The gap between a premium and a subpar filter starts right here with the media. A cheap filter might install smoothly but fail at actual filtration, rendering it useless. High-quality media requires a sophisticated fibrous structure—it must trap harmful particles with precision without creating excessive restriction to oil flow, all while holding more dirt. It’s like a sieve: a finer, tighter mesh cleans better, but is much harder to engineer. The key advantage of premium filter material lies in achieving superior dirt-holding capacity while maintaining this critical balance.

Porosity: Ensuring Uninterrupted Oil Flow

Beyond filtration precision, unobstructed oil flow is crucial. The industry uses “porosity”—the measure of void spaces within the media—as a key metric. For a given thickness, higher porosity allows faster oil passage, which boosts the filter’s overall efficiency.

Burst Strength & Stiffness: The Durability Duo

The physical strength of the media directly dictates the filter’s durability, primarily through burst strength and stiffness. During operation, a pressure differential builds across the media. If the media is weak and ruptures, unfiltered contaminants flood the engine, threatening critical components like crankshafts and piston rings. The toughness of the media is what guarantees sustained protection for your engine.

Other Critical Factors in Filter Quality

Beyond the media, a filter’s dirt-holding capacity determines service life, while its anti-corrosion properties ensure stability in harsh conditions. Details like shell integrity (resisting hidden cracks), gasket sealing performance, and the reliability of the bypass valve safety mechanism are also vital for overall product quality.

The Arrow Oil Filter Advantage: Media Mastery

So, what sets a truly reliable filter apart? At Arrow Oil Filters, the foundation of consistent performance is an uncompromising selection of filter media.

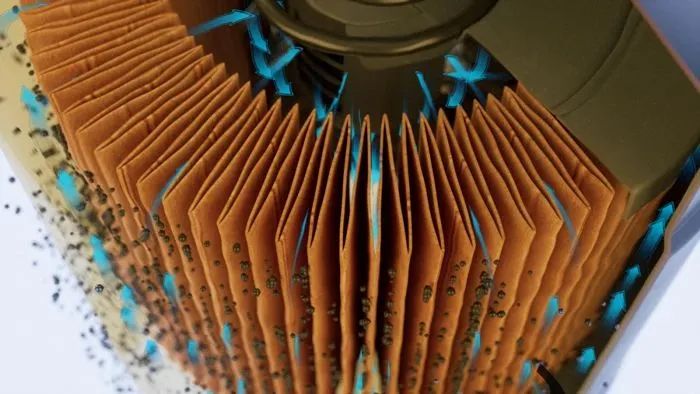

We utilize high-grade media with an 18% PET fiber content. This composition is not just about achieving excellent filtration efficiency; it grants the media outstanding resistance to aging and carbonization, ensuring it lasts through demanding duty cycles.

This premium material is then transformed using precision pleating technology to maximize the effective filtration area within the compact filter housing. Furthermore, our advanced anti-pledge structure during manufacturing optimizes both airflow (during filling) and filtration performance, allowing the inherent advantages of our media to be fully realized.

In summary, an oil filter is far more than a part that’s “good enough if it doesn’t leak.” Choosing a quality oil filter is, at its core, about choosing a trustworthy piece of filter media. It is a fundamental decision for safeguarding your engine’s health and longevity. Don’t just plug a hole—protect your investment with the right filter.

Arrow: Precision Protection, Inside and Out.